|

|

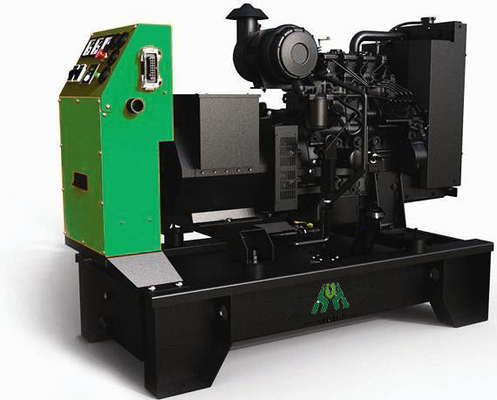

Three Phase Perkins Diesel Genset 8kw 10kVA Silent / Open Type

|

Product Details:

Payment & Shipping Terms:

|

| Output Capacity: | 9/10kVA | Output Power: | 7.2/ 8kW |

|---|---|---|---|

| Type: | Generator Set | Engine: | Perkins |

| Frequency: | 50Hz / 60Hz | Cooling Type: | Water Cooled |

| High Light: | Perkins Diesel Generator Set,Perkins Diesel Genset |

||

Three Phase Perkins Diesel Genset 8kw 10kVA Silent / Open Type

| HDP Series HDP8 / HDP8S |

|

Model |

Standby Power |

Prime Power |

Engine |

Alternator |

Control Panel |

|||

|

KVA |

KW |

KVA |

KW |

Stamford |

Hidier(Optional) |

Model |

||

|

HDP8/S |

10 |

8 |

9 |

7.2 |

403D-11G |

PI044E |

HD7 |

MRS10 |

|

Spec #1 Features |

|

|

1 |

Excitation system: self-excited (AREP and PMG are optional) |

|

2 |

ATS (automatic transfer switch) receptacle |

|

3 |

Lockable battery isolator switch |

|

4 |

Stainless galvanized zinc plates with strong corrosion resistance |

|

5 |

Vibration isolators between the engine/alternator and base frame |

|

6 |

Integrated wiring design |

|

7 |

Base fuel tank for at least 8 hours running |

|

8 |

Equipped with an industrial muffler |

|

9 |

Engine oil pump |

|

10 |

50℃ radiator |

|

11 |

Top lifting and steel base frame with forklift holes |

|

12 |

Drainage for fuel tank |

|

13 |

Complete protection functions and safety labels |

|

14 |

IP54 (soundproof sets), IP56 (control system) |

|

15 |

Water jacket preheater, oil heater are available. |

|

16 |

Double air cleaner, spare parts, special tools are available. |

|

17 |

Custom-made is acceptable |

![]()

![]()

|

Generator Set Model |

Length (L) mm |

Width (W) mm |

Height (H) mm |

Net Weight kg |

|

HDP8 |

1500 |

700 |

1200 |

350 |

|

HDP8 S |

1900 |

700 |

1200 |

530 |

| Spec#2 Engine Perkins 403D-11G |

Air inlet

Mounted air filter

Fuel system

Mechanically governed cassette type fuel injection pump

Split element fuel filter

Lubrication system

Wet steel sump with filler and dipstick

Spin-on full-flow lub oil filter

Cooling system

Thermostatically-controlled system with belt driven coolant pump and pusher fan

Mounted radiator, piping and guards

Electrical equipment

12 volt starter motor and 12 volt 15 amp alternator with DC output

Oil pressure and coolant temperature switches

12 volt shut-off solenoid energised to run

Glow plug cold start aid and heater/starter switch

Flywheel and housing

1500/1800 rev/min

High inertia flywheel to SAE J620 Size 6½ Heavy

Flywheel housing SAE 5 Long

3000 rev/min

High inertia flywheel to SAE J620 Size 6½ Light

Flywheel housing SAE 5 Short

Mountings

Front and rear engine mounting brackets

General Data

Number of cylinders ................................................................. 3

Cylinder arrangement ...........................................Vertical in-line

Cycle .............................................................................4 stroke

Aspiration ..................................................... Naturally aspirated

Combustion system.......................................... Indirect injection

Compression ratio .............................................................. 23:1

Bore and Stroke .................................... 77 x 81 mm (3 x 3.2 in)

Displacement ....................................... 1.131 litres (69 cubic in)

Direction of rotation ................Anti-clockwiseviewed on flywheel

Cooling system..................................................... Water cooled

Total coolant capacity.............................. 5.2 litres (1.4 US gals)

Total lubrication system capacity ............ 4.9 litres (1.3 US gals)

Dimensions

Length ............................................................776 mm (30.5 in)

Width (including mounting brackets) .................449 mm (17.6in)

Height .............................................................700 mm (27.5 in)

Total weight (dry).......................................... 129.2 kg (284.8 lb)

Final weight and dimensions will depend on completed specification.

| Spec#3 Alternator StamfordPI044E |

|

CONTROL SYSTEM |

STANDARD AS480 AVR (SELF EXCITED) |

|||

|

VOLTAGE REGULATION |

± 1.0 % |

|||

|

SUSTAINED SHORT CIRCUIT |

SELF EXCITED MACHINES DO NOT SUSTAIN A SHORT CIRCUIT CURRENT |

|||

|

CONTROL SYSTEM |

AS480 AVR WITH OPTIONAL EXCITATION BOOST SYSTEM (EBS) |

|||

|

SUSTAINED SHORT CIRCUIT |

REFER TO SHORT CIRCUIT DECREMENT CURVE (page 8) |

|||

|

INSULATION SYSTEM |

CLASS H |

|||

|

PROTECTION |

IP23 |

|||

|

RATED POWER FACTOR |

0.8 |

|||

|

STATOR WINDING |

DOUBLE LAYER CONCENTRIC |

|||

|

WINDING PITCH |

TWO THIRDS |

|||

|

WINDING LEADS |

12 |

|||

|

STATOR WDG. RESISTANCE |

1.327 Ohms PER PHASE AT 22°C SERIES STAR CONNECTED |

|||

|

ROTOR WDG. RESISTANCE |

0.415 Ohms at 22°C |

|||

|

EXCITER STATOR RESISTANCE |

17.5 Ohms at 22°C |

|||

|

EXCITER ROTOR RESISTANCE |

0.211 Ohms PER PHASE AT 22°C |

|||

|

EBS STATOR RESISTANCE |

12.9 Ohms at 22°C |

|||

|

R.F.I. SUPPRESSION |

BS EN 61000-6-2 & BS EN 61000-6-4,VDE 0875G, VDE 0875N. refer to factory for others |

|||

|

WAVEFORM DISTORTION |

NO LOAD < 1.5% NON-DISTORTING BALANCED LINEAR LOAD < 5.0% |

|||

|

MAXIMUM OVERSPEED |

2250 Rev/Min |

|||

|

BEARING DRIVE END |

BALL. 6309 - 2RS. (ISO) |

|||

|

BEARING NON-DRIVE END |

BALL. 6306 - 2RS. (ISO) |

|||

|

|

1 BEARING |

2 BEARING |

||

|

|

WITH EBS |

WITHOUT EBS |

WITH EBS |

WITHOUT EBS |

|

WEIGHT COMP. GENERATOR |

80 kg |

78.3 kg |

83 kg |

81.3 kg |

|

WEIGHT WOUND STATOR |

27 kg |

27 kg |

27 kg |

27 kg |

|

WEIGHT WOUND ROTOR |

27.87 kg |

26.17 kg |

28.87 kg |

27.17 kg |

|

WR² INERTIA |

0.0953 kgm2 |

0.0952 kgm2 |

0.097 kgm2 |

0.0953 kgm2 |

|

SHIPPING WEIGHTS in a crate |

100 kg |

98.3 kg |

109 kg |

107.3 kg |

|

PACKING CRATE SIZE |

71 x 51 x 67 (cm) |

71 x 51 x 67 (cm) |

||

| Spec#4 Control System ComAp InteliLite®MRS10 |

InteliLite® MRS 10 and InteliLite®MRS 15 are new integrated controllers for engine control in manual and remote start applications, featuring full gen-set monitoring and protection. InteliLite® controllers are equipped with a powerful graphic display. Icons, symbols and bar graphs for intuitive operation together with high functionality set new standards in gen-set control. Special low temperature (IL-MRS 10 -LT

Features

- Support of engines equipped with Electronic Control Unit – J1939 interface (IL-MRS 15 only)

- Automatic or manual start/stop of the gen-set

- Push buttons for simple control, lamp test

- Graphic back-lit LCD display 128×64 pixels

- 2 LED indicators

- Parameters adjustable via keyboard or PC

- Generator measurements (50/60 Hz): U1-U3, I1-I3, Hz, kW, kVAr, kVArh, kWh

- Selectable protections alarm/ shutdown

- 3 phase Generator protections

- – Over-/under voltage

- – Over-/under frequency

- – Current/voltage asymmetry

- – Overcurrent/overload

- Analog oil pressure, water temperature, fuel level, battery voltage, engine speed (pick-up)

- Configurable programmable

- inputs and outputs

- Warm-up and cooling functions

- RS232 interface (AT-LINK CONV

- cable is necessary for IL-MRS 10)

- Modem communication support (IL-MRS 15 only)

- Dimensions 180×120 mm (front panel)

- Sealed to IP65

| Spec #5 Options |

|

Items |

Options |

Select |

|

Engine |

Water Jacket Preheater |

|

|

Oil Preheater |

|

|

|

Alternator |

Winding Temperature Measuring Instrument |

|

|

Alternator Preheater |

|

|

|

PMG |

|

|

|

Anti-damp and anti-corrosion treatment |

|

|

|

Anti-condensation heater |

|

|

|

Generator Set |

Tools with the machine |

|

|

Fuel System |

Low fuel level alarm |

|

|

Automatic fuel feeding system |

|

|

|

Fuel T-valves |

|

|

|

Canopy |

Trailer |

|

|

Lubricating sys |

Oil with the machine |

|

|

Exhaust Sys. |

Protection board from hotness |

|

|

Cooling Sys. |

Front heat protection |

|

|

Coolant (-30°C) |

|

|

|

Control Panel |

Remote control panel |

|

|

ATS |

|

|

|

DSE |

|

|

|

Voltages |

415/240V |

|

|

400/230V |

|

|

|

380/220V |

|

|

|

220/127V |

|

|

|

200-115V |

|

Contact Person: Mr. Yang Congli(Colin)

Tel: +86 13370160269

Fax: 86-10-59602578

-

24kw 30kVA Perkins Diesel Generators

-

Water Cooling Perkins Diesel Generators

-

10kw Perkins Diesel Generators

-

Stamford Alternstor Perkins Diesel Generators Stainless Galvanized Zinc Plates 22Kw

-

70KW Water Cooled Perkins Diesel Generator Set With Stamford Alternator , 50Hz / 60Hz

-

Silent / Open Type Perkins Diesel Generators 3 Phase With Water Cooling System